What is wood veneer?

Wood veneer is obtained by cutting a tree trunk into thin layers of wood. This process minimizes wood loss during cutting.

Thicknesses vary from 0.5 mm to 3 mm.

The advantages of using veneer are:

• Economical: less expensive than solid wood

• Aesthetic: allows use of rare or precious woods

• Ecological: optimized use of wood resources

• Versatile: adaptable to a wide range of furniture and fittings

• Better dimensional stability than solid wood

1/ Which wood species are used?

Veneer can be obtained from the following types of wood:

- Bamboo : it’s eco-friendly and have a clean and modern appearance

- Cherry : have a rich and warm tone

- White Oak : Wear resistance and natural elegance

- Red Oak : Adds depth and warmth

- Maple: it’s had a smooth and consistent grain, highly impact-resistant veneer

- White Ash : Offers aesthetic versatility with its subtle straight grain, highly impact-resistant veneer

- Hickory: light to medium brown colour with a strong, durable and distinctive grain

- Birch: it’s versatile with subtle grain pattern and light colours

- Walnut: have a dark and rich colours with complex grain pattern

- Knotty pine : Features a rustic look while remaining lightweight and affordable

- Over 100 other types of veneers are available upon request

Veneers with wood species can be produced on 7 different backings, making each veneer sheet different.

2/ The contribution of different backings.

|

The flexibility of wood veneer on 0.010“ thick paper backing allows for a wide range of applications, unlike 0.020” thick paper backing, which offers average flexibility.

Paper backing is available in a wide range of colours and species, and has the advantage of being economical and easy to handle, perfect for curved surfaces or flat lamination.

________

|

.gif) |

|

Fleece (or translucent) backing, with a thickness of 0.005", is almost invisible to the eye, and its flexibility makes it ideal for curved surfaces with very small radii.

This backing is suitable for all species of wood, and is ideal for edge banding.

________

|

.gif) |

|

The phenolic backing, available in all wood species, is 0.020” thick.

Resin-based, this backing is less flexible but provides greater panel stability by reducing the risk of twisting.

It is also more resistant to impact, humidity and water, and reduces the risk of cracking.

________ |

.gif) |

|

If you're looking for a flexible, tough, easy-to-handle backing with Grade A flame resistance, Polyback backing is the one to go for.

With standard or custom dimensions, it's available in 0.020” thickness in a variety of colors that will reduce the black line when trimmed.

It also has the advantage of having the same characteristics as Phenolic backing at a lower cost.

________

|

.gif) |

|

A 2-PLY wood-on-wood backing is made up of two sheets of veneer between which 0.005” paper or urea-formaldehyde-free liquid glue is glued.

The 3-PLY backing consists of 3 sheets of veneer alternating with 2 sheets of 0.005” paper or a Urea formaldehyde-free liquid glue.

Whether long- or short-grained, it's available in all species and represents a good alternative to solid wood: it doesn't make black lines when sorted, and its rigidity eliminates the telegraphy of any imperfections in the material to be veneered.

________

|

.gif) |

.gif) |

|

The special feature of self-adhesive backing is its ease of installation, bypassing the liquid glue application step thanks to its adhesion to any smooth, dust-free surface such as melamine, MDF, particleboard or plywood.

Thickness is 0.002", with custom dimensions available on request. It has the advantage of being usable indoors or out, as it is water and high-temperature resistant (up to 145°C).

________

|

.gif) |

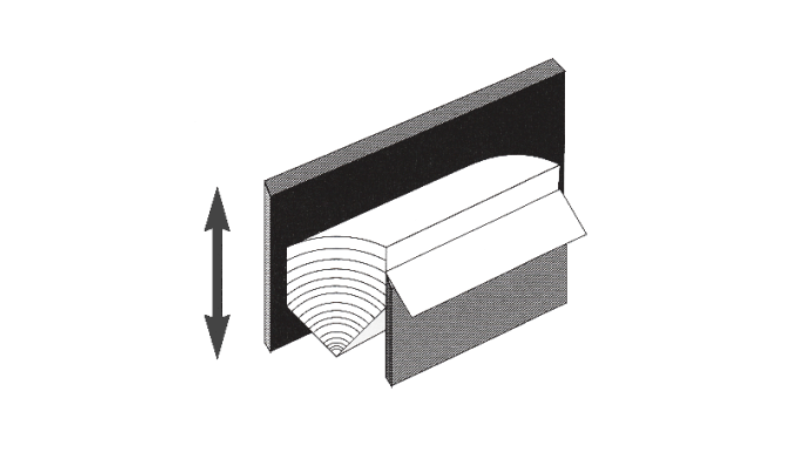

It is also possible to use wood veneer on panels up to 5' x 12', which is quite common in many industries.

The back of the panel is generally made of a lower grade wood veneer, to which a solid panel of:

- MDF

- Particleboard

- Plywood

- HDF PANELS

- Fibrex

- Cora perform

- or Marine plywood

A higher grade wood veneer is then glued to the other side of the panel. All types of veneer are available, allowing for a wide range of colours.

3/ The cutting method best suited to your projects.

There are several methods for cutting veneer.

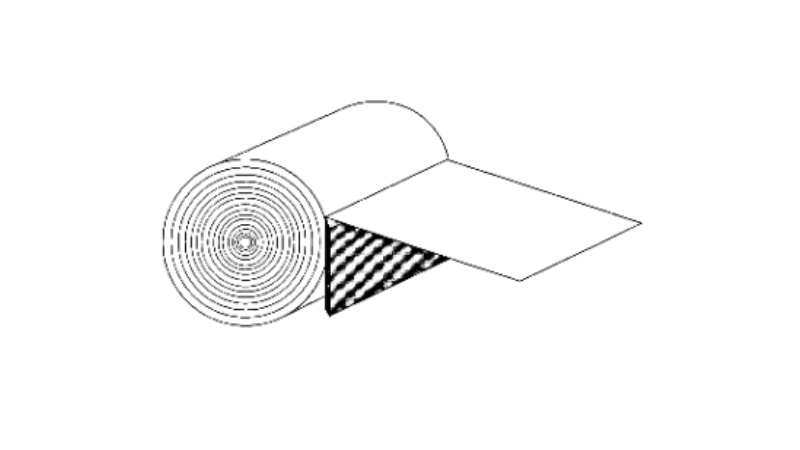

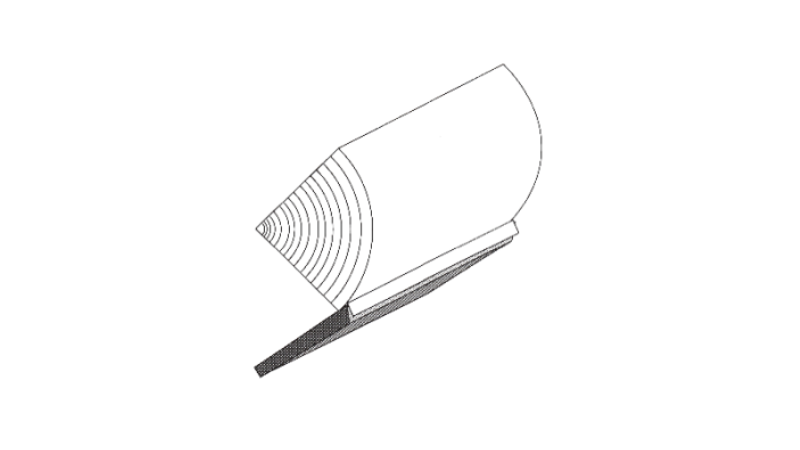

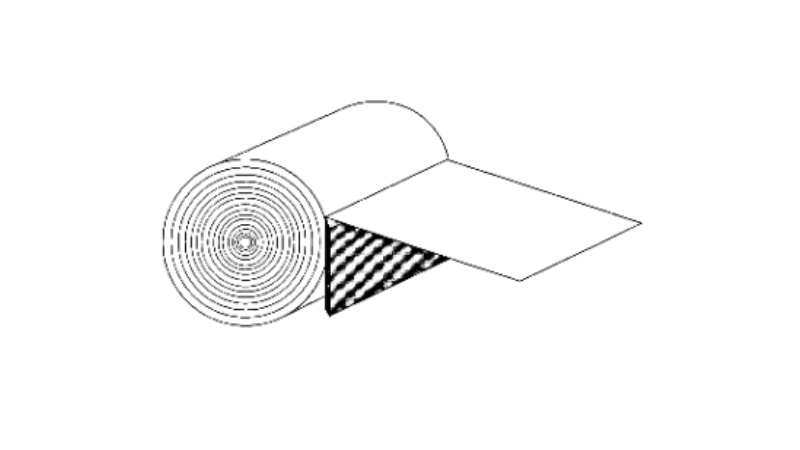

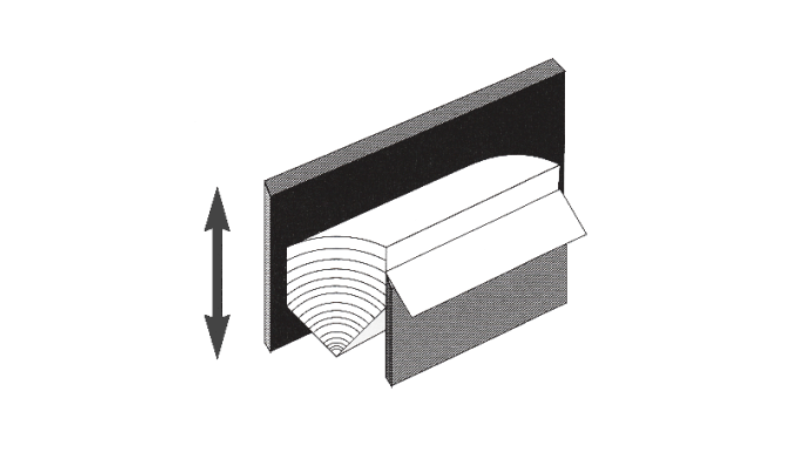

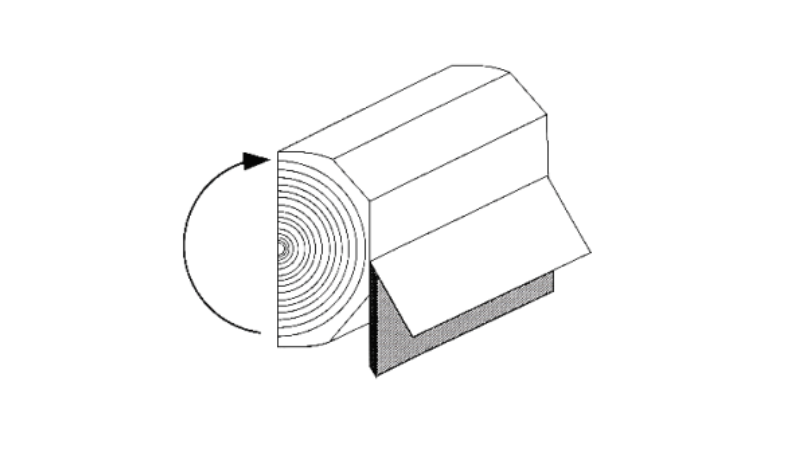

The peeling slicing

If you want a veneer with a wide variety of patterns, peeling is the most suitable process.

Peeling cutting makes it possible to produce veneers in a single piece

This involves rotating the log against the blade and unrolling it into long, wide sheets.

The peeling slicing is offered for the following species:

- Cherry - Poplar

- Maple - Red Oak

The goal is to lower costs by increasing productivity.

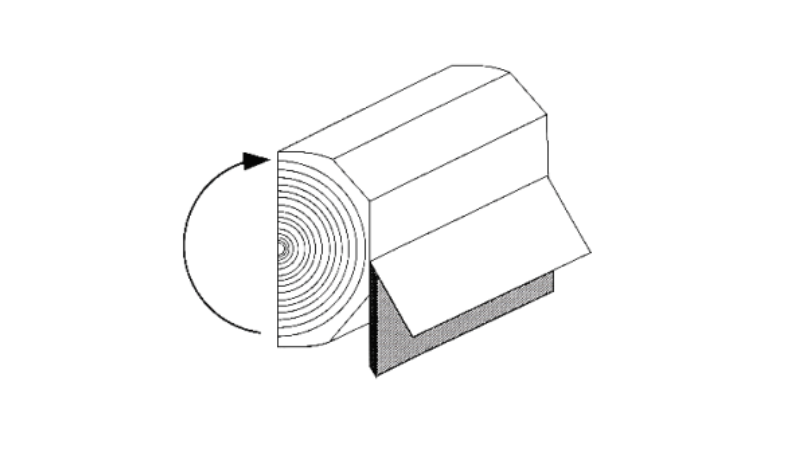

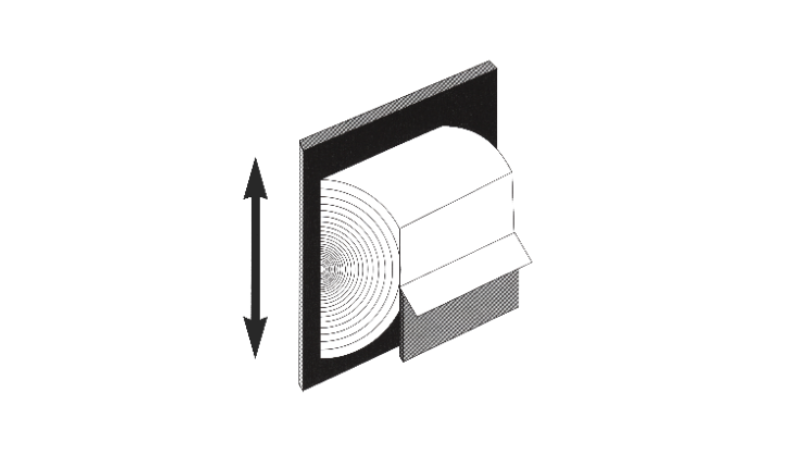

The quarter slicing

For straight-grain veneers, quarter slicing is the ideal solution.

In this approach, the log quarter is mounted on the cutting table so that the growth rings are at right angles to the blade.

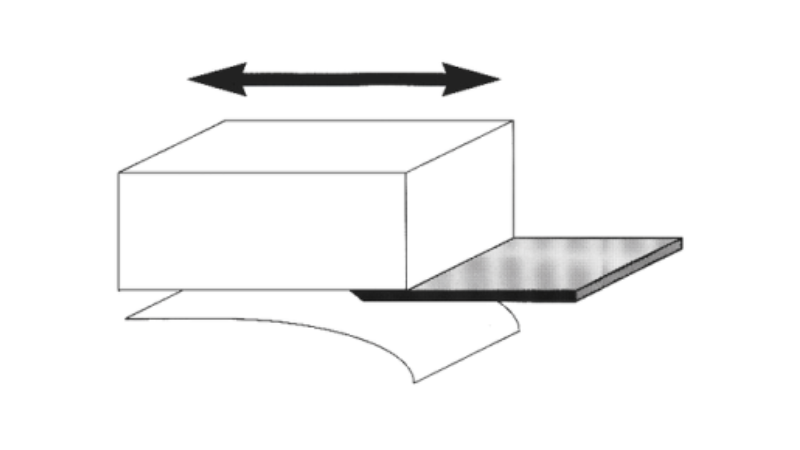

The slice slicing

Slice slicing is done parallel to a line running through the center of the log, and produces a unique pattern.

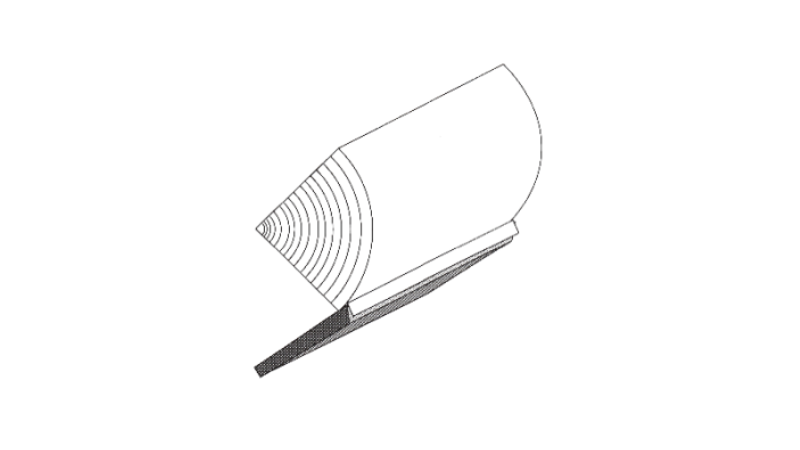

The edge slicing

This slicing method is only used for:

- Red Oak

- White Oak

- White Ash and Brown Ash are used to prevent mismatched pattern in the veneer.

Applicable to all types of oak, this method involves cutting at an angle to the position of the quartelet, giving a combed grain or weft effect.

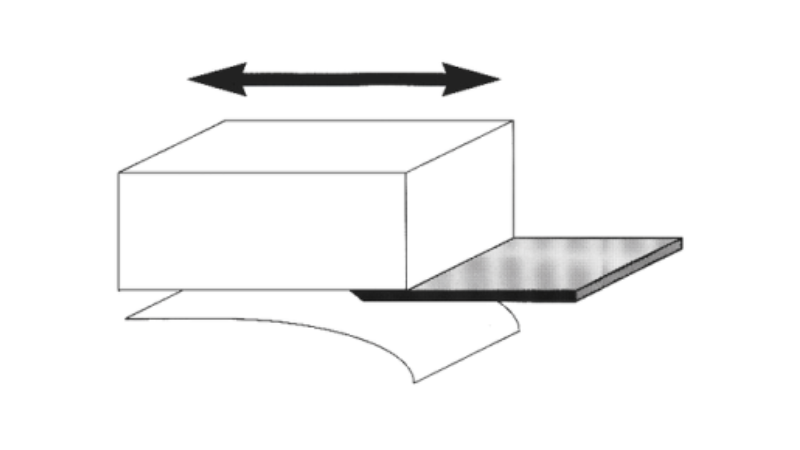

The length slicing

When a fixed blade is used to cut the length of a flat piece of back-sawn wood, we refer to this as length slicing.

This method achieves a perfect look, just like solid-sawn wood.

The semi-uncoiled sliding

And finally, the semi-uncoiled slicing method can be compared to both uncoiling and slicing on pods.

In this method, the bead is mounted on an off-center lathe, producing a varied and unique pattern.

Wood veneer offers an aesthetic and cost-effective way to bring the warmth and elegance of natural wood into your projects.

The different backings of wood veneer play a crucial role in influencing its stability, adhesion, and durability,

allowing the material to be adapted to the technical and aesthetic requirements of each project.

Lightweight, durable, and versatile, it allows for high-end finishes while optimizing resource use.

Looking for premium-quality veneer for your projects?

Commonwealth Plywood Distribution is proud to supply the best brands on the market.

Contact us for personalized advice and samples!

.png)

.gif)

.gif)

.gif)

.gif)

.gif)

.gif)

.gif)

.png)